As the average age of battery energy storage system (BESS) sites in the US approach 4 years old, many BESS operators and owners may be asking themselves if they can get more out of their systems. Fortunately, FlexGen has a dedicated Performance Engineering team to not just answer that question but also provide data-informed and actionable insights to optimize your battery storage assets. Jonny Hoffman, FlexGen Manager of System Operations and Performance, gives us a look into how the Performance Engineering team operates and how crucial their services are to getting the most out of a BESS site throughout its lifetime.

Tell us about your role at FlexGen.

Jonny: I lead FlexGen’s Remote Operations Center (ROC) and Performance Engineering (PE) team, delivering two complementary services: Lifecycle Solutions and Analytical Site Assessments.

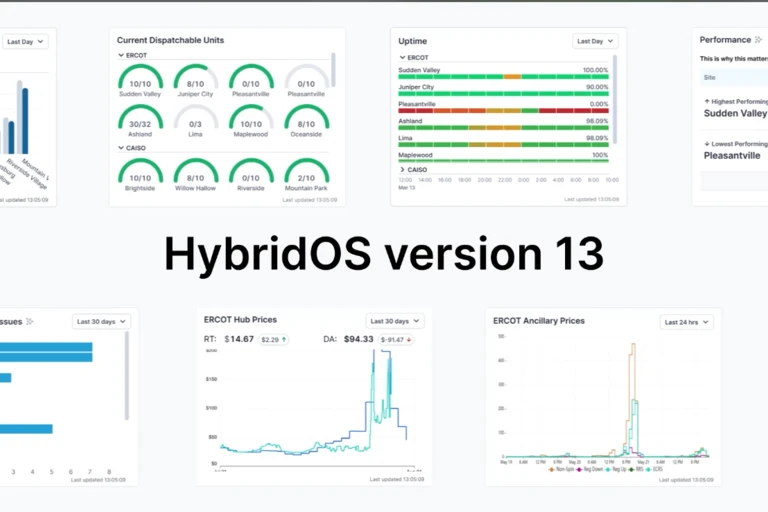

For Lifecycle Solutions, we ensure our customers’ BESS sites operate safely and profitably long after commissioning. That includes 24/7 remote monitoring, preventative maintenance scheduling, and performance guarantees. With automated alerts via HybridOS, our real-time responsiveness, and our proactive approach, we keep faults and other issues from escalating that can cause downtime and early asset degradation.

The PE team offers an Analytical Site Assessment (ASA) for third-party integrated systems that aren’t meeting performance expectations. We feed raw site data into HybridOS Analyze and apply AI-powered analytics to uncover issues—like cell or rack imbalances, EMS inefficiencies, thermal derates, or PCS faults. The result is a data-driven, prioritized action plan with precise root-cause diagnostics and targeted remediation steps—empowering you to maximize uptime, usable capacity, and overall ROI.

On any given day, I work cross-functionally with commissioning engineers, power systems specialists, integration teams, asset managers, field technicians, and software developer—ensuring that ROC insights and PE findings drive real-world performance improvements and help refine our EMS software through continuous feedback.

Tell us a little about how the Analytical Site Assessment (ASA) came about.

Jonny: The utility-scale BESS market has evolved rapidly, and many of the earliest deployments are now entering their mid-life phase—often revealing that real-world performance falls short of initial expectations. In many cases, these shortfalls stem from a combination of aging hardware, limitations in EMS and firmware, and a lack of visibility into how systems operate under dynamic grid conditions. Early integrators often lacked the tools or operational expertise to diagnose these issues with the level of precision required.

When the first wave of battery storage projects came online there was a common assumption that, once commissioned, the systems would operate reliably with minimal intervention. In reality, these assets are complex to operate. Paired with rapidly evolving hardware platforms, shifting grid requirements, and, in many cases, EMS providers that are no longer in business or lack the resources to provide adequate post-commissioning support, BESS operators and owners are faced with a host of challenges. Performance optimization requires deep domain expertise, the ability to interpret tens of thousands of data points in real time, and close coordination across engineering, software, and operations teams.

At FlexGen, we recognized a recurring pattern across the market—sites owners were asking why they weren’t getting more from the BESS. That realization led to the creation of the Analytical Site Assessment (ASA), a service that leverages our EMS, controls, analytics, and integration expertise to deliver independent, data-driven diagnostics and remediation plans for third-party sites. We take raw telemetry, apply advanced analytics, and translate it into actionable insights—helping owners understand not just that a problem exists, but why, and how to fix it.

What can a BESS operator or owner expect to gain from an ASA?

Jonny: Those who consult with FlexGen through an ASA can expect 4 outputs from our Performance Engineering team: root-cause diagnostics, an actionable roadmap for performance improvement, a performance baseline and forecast, and strategic lifecycle management recommendations.

When we diagnose your site’s performance data, we’re looking for hardware faults, EMS/configuration issues, or operational missteps that drive derating and capacity shortfalls. Once we’ve determined the root cause of the performance issues, we provide a prioritized and cost-benefit driven list of recommended fixes. These recommendations range from BMS threshold tweaks and firmware updates to EMS algorithm optimization and procedural changes. If a component replacement is deemed necessary, our global supply chain team has real-time insights into the market’s most proven and cost-efficient options.

ASA findings can also support hardware warranty claims. By isolating failure signatures and correlating them with component-level telemetry, ASA findings provide data-backed evidence to substantiate OEM warranty claims, which accelerates resolution timelines and reduces out-of-pocket replacement costs.

Next, we quantify baseline metrics and provide forecasted performance to allow owners to model future revenue and maintenance schedules and measure improvements. With improved clarity around available capacity, efficiency losses, and degradation trends, the ASA can refine revenue forecasts, adjust total cost of ownership (TCO) assumptions, and support more accurate financial planning for operators and investors alike. And, we arm our ASA customers with best practices for the entire lifetime of their assets, not just a one-time fix. We help owners safeguard ROI by directing when to schedule preventative maintenance, asset augmentation, annual capacity tests, or deeper hardware inspections.

What sets this approach apart is our ability to diagnose issues across all three critical domains—hardware, software, and operations—and to contextualize how each one affects the others. A site won’t perform optimally if only one layer is addressed. True performance recovery requires a coordinated strategy across these domains, and that’s exactly what the ASA delivers.

In your experience, what are some of the most common reasons for an underperforming site?

Jonny: The most common reasons for an underperforming site fall into the three categories I mentioned before: hardware, software, and operational processes.

Under hardware, cell imbalances and aging hardware are at the top of the list. These will gradually fade capacity and lead to voltage cutouts or module mismatches that erode usable energy. And, if hardware experiences excessive ambient or cabinet temperatures the system may trigger conservative control limits. Additionally, persistent or intermittent issues with the power conversions system (PCS) can significantly impact availability and energy throughput.

As far as common software pitfalls, EMS/algorithm misconfiguration seriously impacts BESS operations. Unoptimized control logic, over- or under-aggressive deadbands, state of charge (SOC) buffers that don’t align with site-specific performance characteristics, and inadequate handling of charge/discharge transitions can all contribute to underperformance.

No two BESS sites are the same, so setting operational practices with care is key. Dispatch schedules that overlook ancillary service obligations or site-specific constraints lead to unplanned derates.

These issues—individually and collectively—undermine system availability, reduce usable capacity, and compromise financial performance. Left unresolved, these issues can lead to missed market opportunities, accelerated degradation, financial underperformance, and even liquidated damages under Power Purchase Agreements (PPAs). Identifying and addressing them proactively is critical to maintaining long-term reliability, avoiding financial penalties, and maximizing the value of the asset.

Tell us about why and when a BESS owner may choose an EMS Retrofit.

Jonny: At the conclusion of an ASA, we typically identify issues across the three major categories I mentioned before. In many cases, we can support the owner in remediating hardware problems and guide their team toward improved operational decision-making. However, if EMS logic is fundamentally misaligned with site conditions or market requirements, no amount of hardware or procedural optimization will unlock full system performance.

This is where an EMS retrofit becomes essential. If the existing EMS lacks flexibility, relies on outdated control structures, or cannot accommodate advanced state-of-the-art features, the site will continue to underperform, even with all other issues resolved.

Migrating to FlexGen’s HybridOS EMS, and BMS when applicable, closes that final gap. It ensures that hardware, operations, and software are all working in harmony to empower the asset to meet performance expectations, reduce downtime, and maximize ROI. In short, you can fix the hardware and operational behavior, but if you don’t address the EMS, your system will still fall short. All three elements must be aligned for the site to operate at its full potential.

What’s one piece of advice you would give to every BESS operator or owner embarking on their first energy storage project?

Jonny: I would tell them the top three things to remember:

- Engineer for lifecycle resilience, not just mechanical completion. Too often, BESS projects are optimized around day-one commissioning metrics, while long-term performance strategy is treated as an afterthought. My advice: choose an EMS platform that enables real-time observability, adaptive control logic, and long-horizon analytics.

- Establish a roadmap for periodic performance assessments, and embed feedback loops between operations, engineering, and market teams.

- Most importantly, choose partners with deep experience in energy storage, cross-functional technical expertise, and a proven track record of long-term support. BESS isn’t a static asset—it’s a dynamic system operating in a volatile environment. Sustained value comes from continuous optimization, early fault detection, and the ability to evolve with regulatory, market, and hardware changes over time.

I'd also like to emphasize—don’t panic if things aren’t going as expected! Reach out to FlexGen early to understand your options and set an action plan in motion.

Learn more about your options and reach out to an expert here.